About Us

About UACJ Extrusion Corporation

As a member of the world-class UACJ Group, UACJ Extrusion Corporation uses a variety of extrusion methods to produce various types of tubes, rods, shaped materials, and other components used in the automotive field, transportation equipment, and industrial equipment.

In addition to meeting diversifying needs, such as high-strength and difficult-to-shape components and processed products that make full use of processing technology in accordance with customer requests, we are also focusing on further product development by creating our own original products to make the needs and wants of our customers a reality by focusing on new areas.

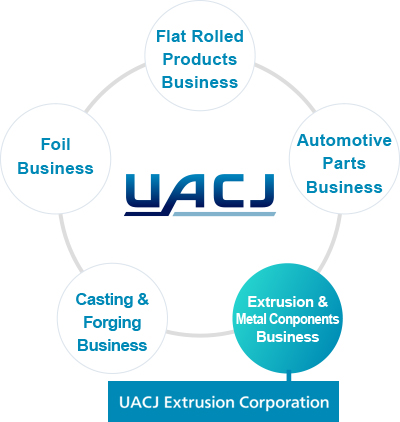

1. Overall Strengths of the UACJ Group

The UACJ Group is Japan’s foremost and one of the few “comprehensive aluminum manufacturers” in the world active in the aluminum flat rolled products, automotive parts, extrusion & metal components, casting & forging and foil businesses. We meet the needs of a wide range of industries by offering products from beverage cans that we use in our everyday lives to automotive components, electronic equipment, medical supplies, and even rocket and aircraft components.

As a member of the UACJ Group, UACJ Extrusion Corporation leads and plays a part in the extrusion business by adding new value with its technological strength of extruded material.

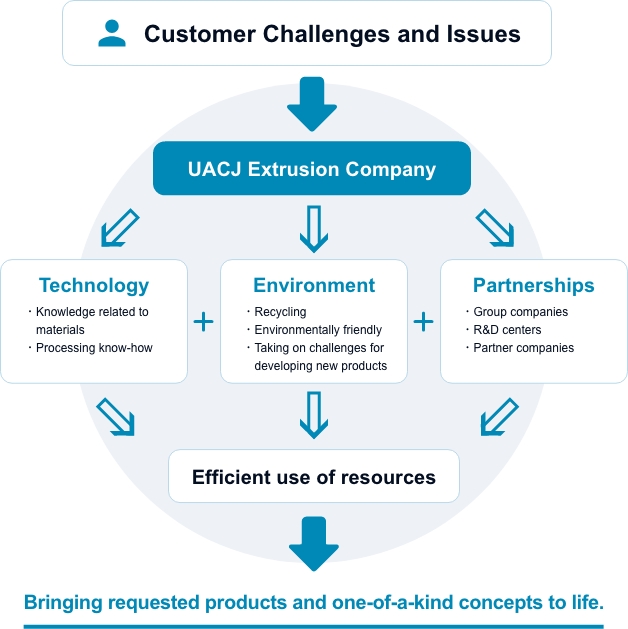

2. Realization of products that customers want as well as original products

In addition to meeting diversifying needs, such as high-strength and difficult-to-shape components and processed products that make full use of processing technology in accordance with customer requests, we are also focusing on further product development by creating our own original products to make the needs and wants of our customers a reality by focusing on new areas.

3. Group Research and Development Division handles a wide range of activities from alloy development to product development

The Group’s R&D Center of the group enables us to not only manufacture and process materials but also develop alloys, thus enabling us to respond quickly to customer needs and promote innovative products and technology development that is one step ahead of the times.

R&D Center Strengths

- Alloy Development

- Product Development

- Production Technology Support

Main Features of the UACJ Extrusion Corporation

1. Extrusion-related facilities that meet high quality requirements which are among the best available in Japan

Aircraft, rockets, and other products that are required to be manufactured with high dimensional accuracy, with large diameters, and with long lengths require high output indirect extruders in order to be created. The UACJ Extrusion Corporation Group owns seven of the more than ten indirect extrusion machines that exist in Japan, uses a large 5,600-ton extruder that uses both direct and indirect extrusion methods, and also uses two vertical quenching furnaces, which is unique in Japan, to meet these needs.

2. Ability to respond to ever-changing automobile part requirements

In order to respond to automobile part requirements that become more sophisticated as time goes on, we provide the UACJ Group and other customers with components that make full use of 7000 series alloys, which offer a particularly high level of strength and deliver stable quality. By introducing a state-of-the-art extruder in Nagoya, we are able to meet all needs.

3. Ability to create products to quickly solve customer issues

Through extensive experience, we have accumulated knowledge on alloy and mold design. For example, in the case of multi-hole tubes for automotive heat exchangers, we contribute to solving customer problems by reducing the weight by using thinner walls and improving electrothermal performance.