Products

Ultraprecision Extruded Multi-Hole Aluminum Tubes

Ultra-precision aluminum extrusion technology for high-performance heat exchangers

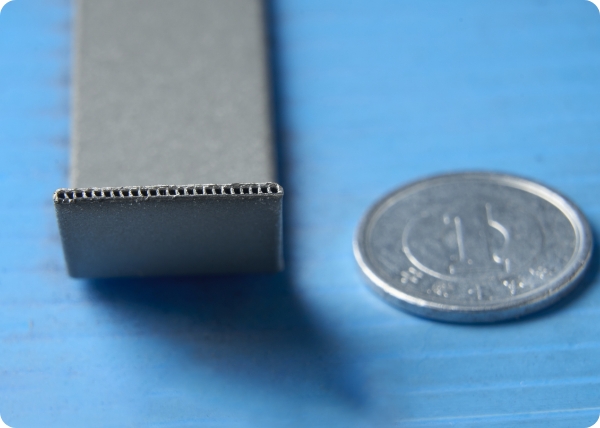

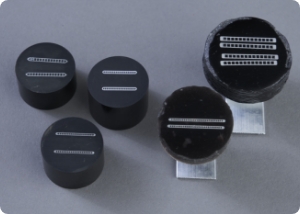

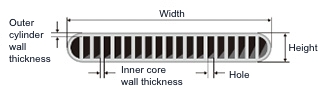

Flat multi-hole aluminum tubes with multiple tiny holes offer improved heat exchange performance and are used in automotive air conditioners and outdoor units of room air conditioners.

- Can also be manufactured using 3000 series alloys for high pressure Co2 refrigerant applications.

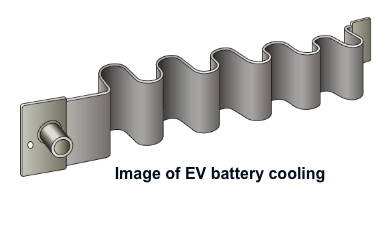

- By having several inner ribs in its cross section, these tubes can withstand multiple bending processing in the longitudinal direction, keeping passages for refrigerant and cooling water unobstructed.

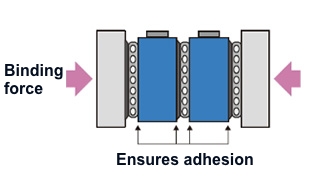

- In recent years, these tubes are also being used more to provide a cooling system for EV and FCV batteries.

Features

- Use of type 1000 alloy, which has good heat conductivity, with many tiny holes, delivers excellent heat transfer performance.

- Cross section offers a high degree of freedom in terms of design, so the tiny holes can be square, round, or rib shaped, realizing a much narrower tolerance range among extruded materials.

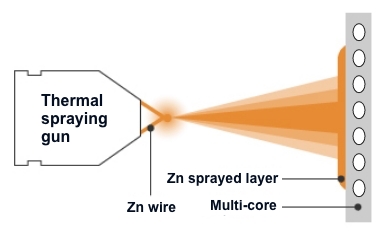

- The surface of the multi-hole tube can be sprayed with zinc or coated with flux to improve corrosion resistance.

Scope of allowable manufacturing

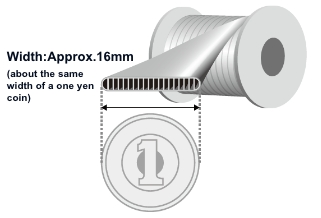

| Width (W) | 12 to 23 mm |

|---|---|

| Height (H) | 1.0 to 3.0 mm |

| Wall Thickness (t) | 0.15 to 0.4 mm |

| Holes | In addition to square-shaped holes, tubes can also be made with round holes and rib-shaped holes. |

Product technology

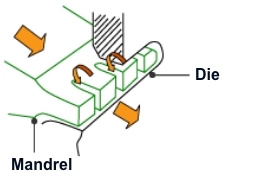

Ultra-precise extrusion technology

Zinc arc spraying technology