Products

High-temperature Strength, Creep-resistant Alloys

These alloys developed by our company offer good production characteristics while maintaining excellent high-temperature strength, creep resistance, and heat transfer properties.

Aluminum tubes used in photocopier heat rolls are required to have creep resistance, high-temperature strength, and heat transfer characteristics. Although 5000 series alloys such as A5052 have been used in the past, the CM10 alloy developed by our company offers better creep resistance, high temperature strength, and heat transfer properties than 5000 series alloys. Recently, we have developed a new alloy called CM211 which allows for improved productivity while maintaining the characteristics of CM10.

Features

- Offer better creep resistance, high temperature strength, and heat transfer properties than ordinary 5000 series alloys.

- Both CM10 and CM211 can be used for port hole extrusion.

Mechanical Properties

| Material | O Temper, Tensile Characteristics at Room Temperature | High-temperature Tensile Characteristics at 200°C | ||||

|---|---|---|---|---|---|---|

| Tensile Strength (MPa) | Resistance (MPa) | Elongation (%) | Tensile Strength (N/mm2) | Resistance (N/mm2) | Elongation (%) | |

| CM211 | 217 | 134 | 27 | 197 | 130 | 20 |

| CM10 | 223 | 96 | 28 | 164 | 69 | 26 |

| A5052 | 195 | 90 | 30 | 115 | 75 | 60 |

| A5056 | 250 | 95 | 35 | – | – | – |

| A6063 | 90 | 48 | 35 | 55 | 41 | 65 |

| A6061 | 125 | 55 | 30 | 75 | 55 | 60 |

Note 1: Some of the data for 5052, 5056, 6061 and 6063 are from Properties of Aluminum Alloy, published by the Aluminum Association.

. *2: High temperature tensile characteristics data for 5052, 5056, 6061 and 6063 based on testing at 205°C.

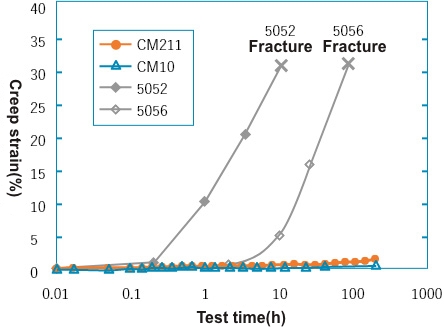

Creep Characteristics

Conditions

Temperature: 200°C

Stress: 80 MPa

Time: 0 to 200 hours

| Material | Rupture Time (h) |

|---|---|

| CM211-O | > 200 unruptured |

| CM10-O | > 200 unruptured |

Creep Characteristics

| Material | Heat Resistance | Heat Conductivity | Porthole Extrusion | Specific Gravity | Young’s Modulus (kN/mm2) | Heat Conduction Rate※1 (W/(m, K)) | Specific Heat (J/kg/K) |

|---|---|---|---|---|---|---|---|

| CM211-O | ◎ | ◯ | ◯ | 2.73 | 70.1 | 163 | 894 |

| CM10-O | ◎ | ◯ | ◯ | 2.73 | 70.0 | 157 | 891 |

| A5052-O | △ | △ | ✕ | 2.65 | 69.3 | 151 | 892 |

| A5056-O | △ | ✕ | ✕ | 2.61 | 71.7 | 134 | 892 |

| A6063-T6※2 | ✕ | ◎ | ◎ | 2.67 | 68.3 | 167※2 | 896 |

| A6061-T6※2 | ✕ | ◯ | ◯ | 2.69 | 68.3 | 201※2 | 900 |

*1 Measurement values obtained using laser flash method

*2: Values for 6063 and 6061 (T6 only) are from “Metals Handbook”, ASM, vol.10 (1990)