Our Business

UACJ is ready to meet your needs for various extruded products by utilizing the most suitable factory and manufacturing method.

We can meet all extrusion needs for tubes, bars and shaped materials, and we also offer processed products that utilize such materials.

Manufacturing Process for Extruded Materials

Melting and Casting Process

New ingots or recycled raw materials are melted to produce aluminum alloy billets of a predetermined composition. The casting size is matched to the size of the extruded material.

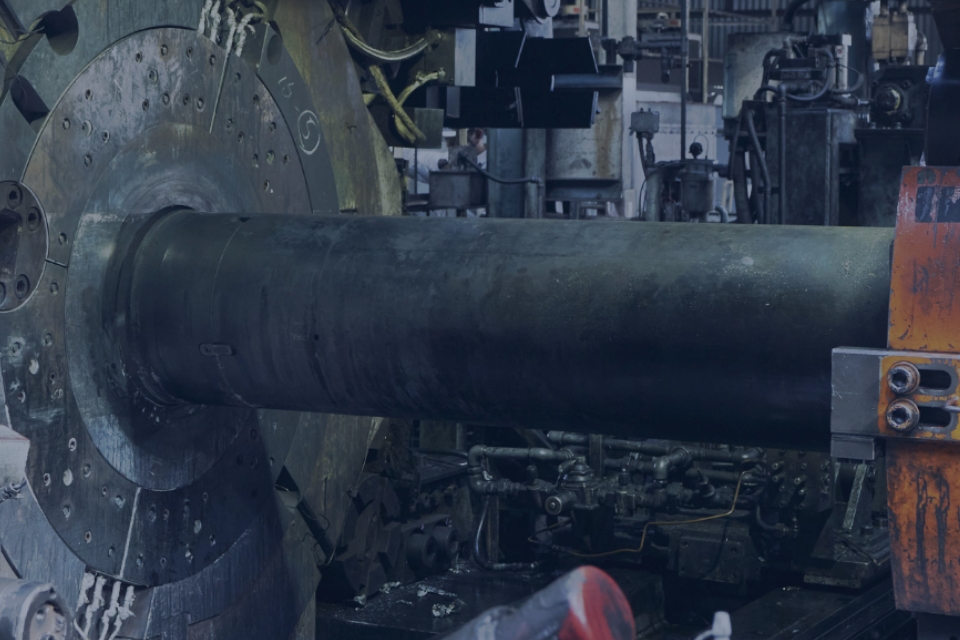

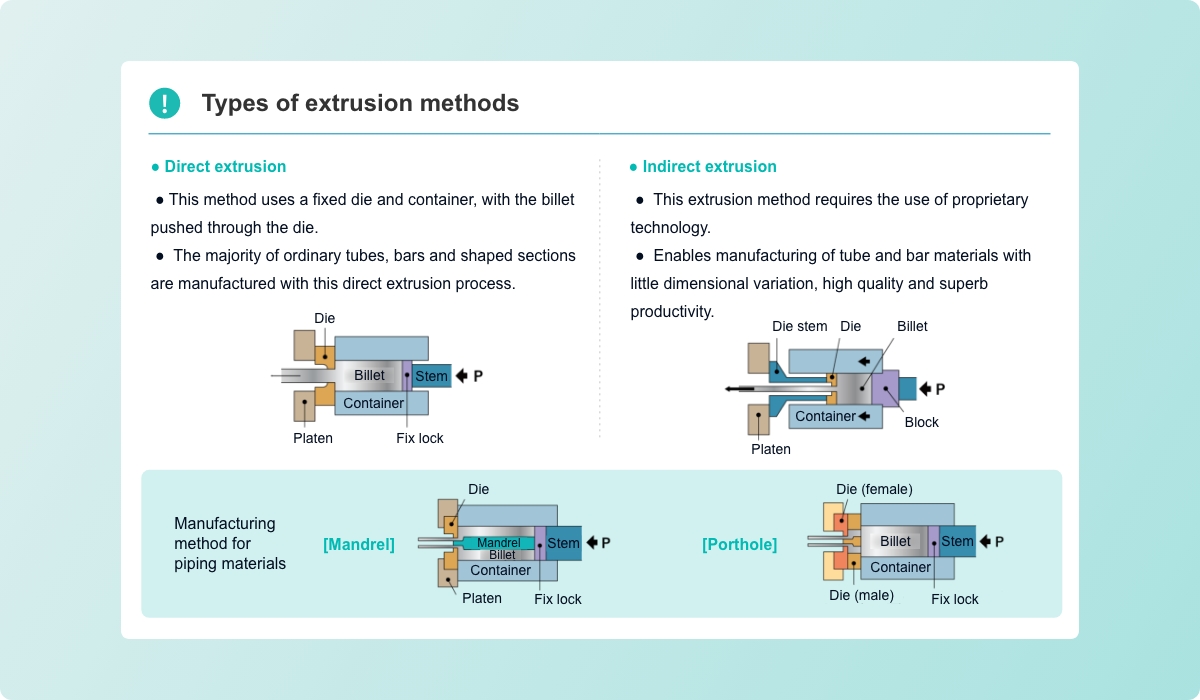

Extrusion Process

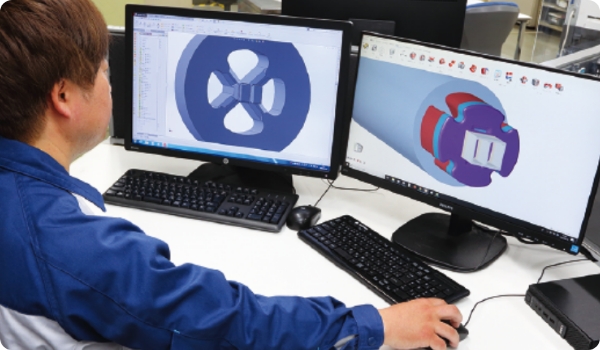

We have introduced a state-of-the-art CAD system for the design of dies used for extrusion and are working on designs of dies optimal for product shape. Using such dies, aluminum is made into various shapes by passing molds while hot.

Finishing Process

After extrusion, the material is cold drawn to improve dimensional accuracy and strength, corrected for bending, etc., and heat-treated to adjust its strength to meet requirements.

Die Design

We have introduced a state-of-the-art CAD system for the design of dies used for extrusion and are working on designs of dies optimal for product shape. Using such dies, aluminum is made into various shapes by passing molds while hot.

Die Types

Solid Shape

Solid die Hollow Shape

Male die Female die Hollow die