Products

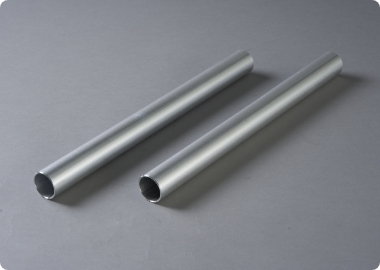

“MS Drum” Uncut High-Precision Drawn Aluminum Pipe for Photoconductor Drums

Our unique technology achieves high dimensional accuracy suitable for photoconductor drum applications by using precision extrusion and cold-drawing processes to achieve a mirror surface.

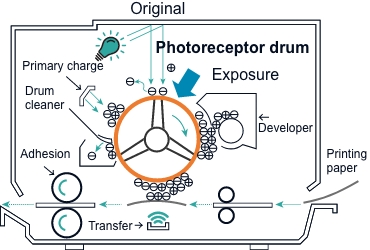

Photosensitive drums are said to be the heart of laser printers and copiers. High-precision drawn aluminum pipes are the materials used in such drums. Through its own development, UACJ has succeeded in making mirror surfaces only by precision extrusion and cold-drawing processes, eliminating the need for conventional machining and mirror surface processing.

Features

- Cold-drawing creates an excellent surface and reduce surface-machining processes.

- Achieves high dimensional precision (exterior and interior diameters, chatter pattern).

- Organic solvents are unnecessary, allowing environmentally friendly water washing and eliminating the need for oil during production.

- Automatic testers are used to test all products for dimensional accuracy and surface quality.

- Stable product quality is ensured through consistent manufacturing process management spanning casting, extrusion, drawing and testing.

Product Characteristics

Superb dimensional precision and coated optical surface characteristics

| Tolerance on outside diameter | Approximately 1/5 of JIS |

|---|---|

| Chatter pattern*1 | 35 μm or less |

| Surface roughness*2 | Ry ≦ 2 μm |

*1 Measured at center, when tubes are supported at both ends and rotated *2 Maximum height

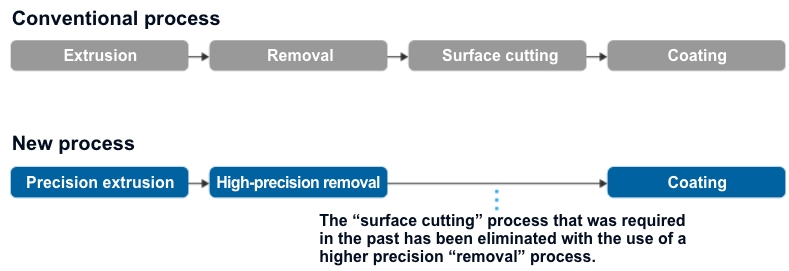

Manufacturing process

Comparison of conventional and new processes