Products

CB Series/KS Series Environment-Friendly, Free-Cutting Aluminum Alloys

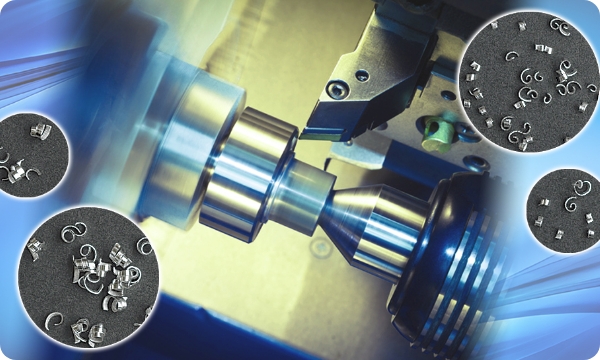

Our free-cutting aluminum alloys are environmentally-friendly, do not contain lead, and offer improved chip control performance.

In recent years, a global policy to reduce or eliminate the use of environmentally hazardous substances has been established. Materials used in automobiles and electrical components must also comply with this policy. In order to respond to this, we have developed environmentally-friendly free-cutting aluminum alloys that do not contain lead and offer improved chip control performance.

Features

- Machinability – Ideal as a replacement for the 2000 series of lead-added alloys.

KS26 and CB256 are suitable for use in applications where temperatures reach above 100°C, effective replacements for 2017 alloy. - Mechanical properties – Strength close to that of 2000 series of lead-added alloys can be obtained.

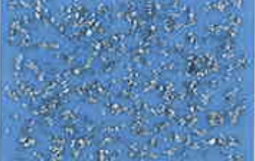

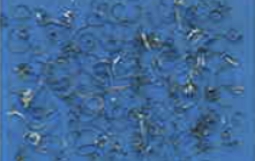

- Chip control performance – Offers machinability equivalent to that of 2000 series of lead-added alloys.

KS26 and CB256 offer better chip control performance than 2017 alloy.

– Please consult with us in advance because lead-free free-cutting alloys may not be suitable in certain operating environments.

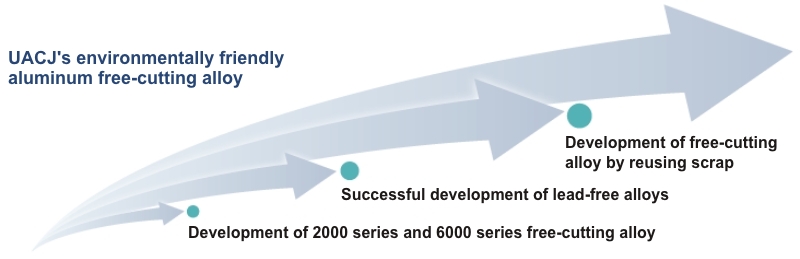

History of the Development of Free-cutting Alloys

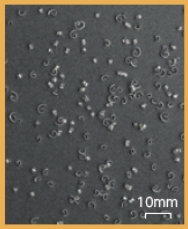

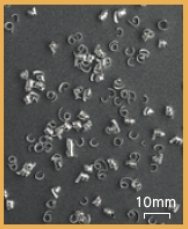

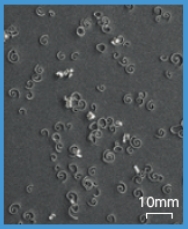

Chip Processing Performance (chip appearance)

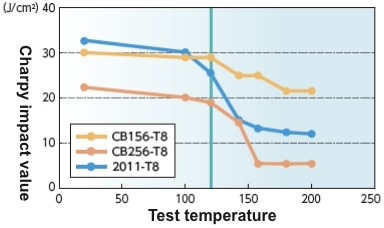

Charpy impact value

Main Applications

| Alloy | Material | Mechanical Properties | Environmental Responsiveness | Chip Control Performance | Surface Processability | Corrosion Resistance | High Temperature Resistance | ||

|---|---|---|---|---|---|---|---|---|---|

| Tensile Strength (N/mm2) | Resistance (N/mm2) | Elongation (%) | |||||||

| 2000 series Pb-free material | CB156-T8 | 420 | 320 | 15 | ◯ | ◎ | △ | △ | ◯~△ |

| KS28S-T8 | 420 | 330 | 23 | ◯ | ◎ | △ | △ | ◯~△ | |

| 2000 series Pb- and Sn-free material | CB256-T8 | 440 | 330 | 15 | ◎ | ◯ | △ | △ | ◎ |

| KS26-T8 | 430 | 340 | 25 | ◎ | ◯ | △ | △ | ◎ | |

| 2000 series conventional materials | 2011-T8 | 440 | 330 | 15 | ✕ | ◎ | △ | △ | ◯ |

| 2017-T4 | 450 | 270 | 25 | ◎ | △ | △ | △ | ◯ | |

| 6000 series conventional materials | KS69S-T8 | 345 | 330 | 18 | ◯ | ◯ | ◯ | ◯ | ◯ |

| GT209-T8 | 300 | 270 | 16 | ◯ | ◯ | ◯ | ◯ | ◯ | |

* ◎: Very good, ◯: Good, △: Somewhat Poor, X: Poor

Additional Information

– CB156 and KS28S with Sn additive have been confirmed to dissolve when in contact with alcohol-containing liquids.

– Elevated temperatures must be avoided when working with 2000 series free-cutting alloys, which contain elements with low melting points and is brittle at high temperatures above 120°C or higher.

Type 6000 free-cutting alloys do not exhibit the same sudden embrittlement as with 2000 series alloys, but KS69S (with Sn+Bi additives) alloys show the trend to be somewhat brittle at temperatures above 160°C.

– Please consult with us in advance because lead-free free-cutting alloys may not be suitable in certain operating environments.